lasercongress.org / Press Releases /Detail

Networking 4.0: International Laser Technology Congress AKL’16 Shows New Ways of Cooperations

The International Laser Technology Congress AKL’16, Europe’s leading conference on the applications of laser technology, was held in Aachen, April 27-29, 2016. This year, the congress focused on micro and macro processing, as well as offering special forums dealing with process monitoring and additive manufacturing. The opening of the Photonics Cluster on the RWTH Aachen Campus begins a new chapter in the cooperation between research and industry.

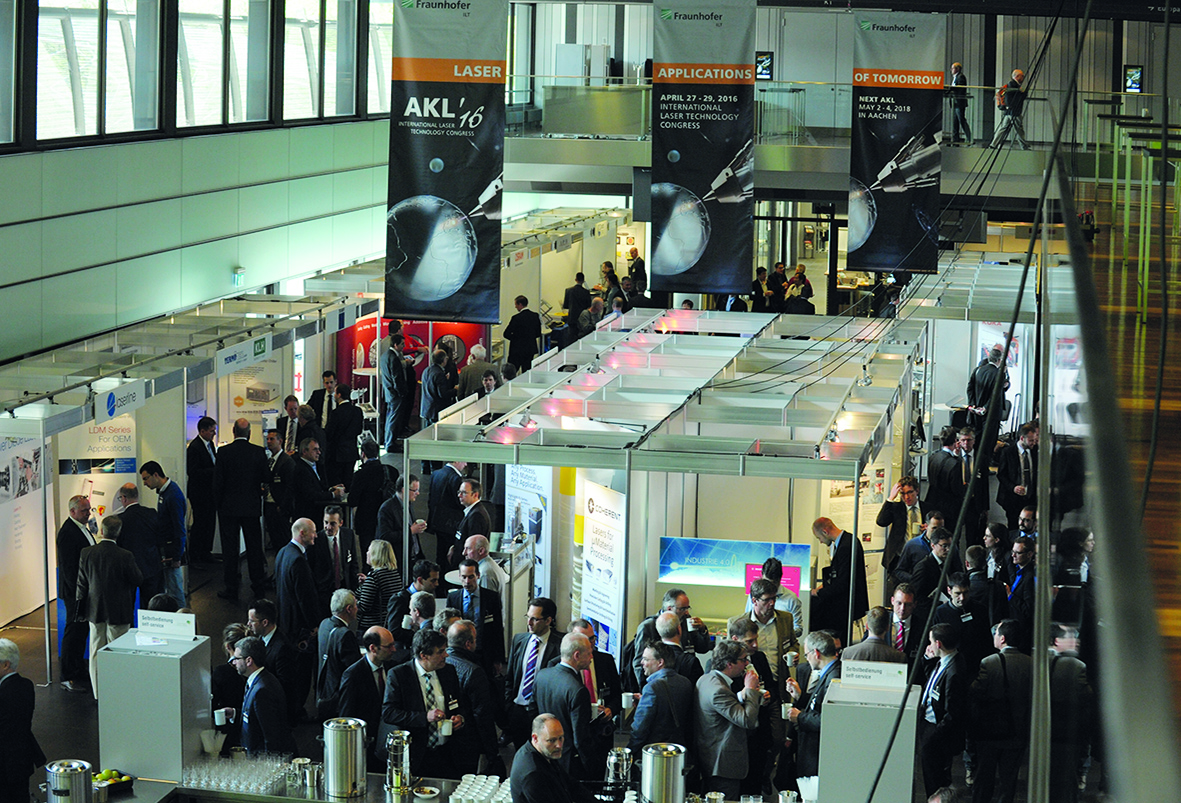

Every two years, the Fraunhofer Institute for Laser Technology ILT holds the International Laser Technology Congress AKL in Aachen. Europe’s biggest industry conference for applied laser technology in production drew more than 690 participants this year – an increase of 10% on 2014. The conference has also become more international, this year attracting 196 visitors from abroad, from a total of 27 different countries. The sponsors’ display also filled up very early on, with 52 companies represented.

The core of the AKL program was the specialist conference with three separate sessions, but on top of that there were also a variety of additional events, including an introductory seminar on laser technology, specialist forums on process monitoring and additive manufacturing, and a number of evening events. Lasertechnik Live, a guide to the laser application center of the institute, proved extremely popular this year, with 91 live presentations of current projects underway at Fraunhofer ILT.

A definite conference highlight was the presentation of the 2016 Laser Technology Innovation Award in the coronation hall of the Aachen town hall. The prize is awarded by Arbeitskreis Lasertechnik e.V. and the European Laser Institute ELI in recognition of an outstanding contribution in the field of industrial laser technology. This year, first place and its prize money of 10,000 euros went to Dr. Armand Pruijmboom and his team at Philips Photonics GmbH Aachen for their development of VCSEL arrays as a new high-performance laser technology for the digital heat treatment of workpieces.

Improving Efficiency and the Commoditization of Laser Sources

AKL’s specialist technology conference examines every step of beam source development, right up to the most diverse applications. This year revealed multiple trends. First of all, it seems that beam source development is focusing less on disruptive technologies and more on improving the efficiency and performance of existing ones. Fiber lasers are now available at powers of up to 100 kW, while direct diode systems are reaching the 50 kW mark. Initial investigations at Fraunhofer ILT also confirm that diode lasers are now suitable for laser cutting. At the same time, we are seeing that systems are becoming more and more comparable, with commoditization leading to a price war and further consolidation within the sector.

Ultrafast lasers are still relatively new to system providers‘ portfolios. The market for systems up to around 150 W is growing disproportionately quickly, and applications in the electronics, semiconductor and consumer goods industries were presented at the AKL. The missing ingredient is productivity. One solution is the multi-beam system offered by Aachen start-up Pulsar Photonics, while the availability of suitable laser cables (PT Photonic Tools) should also help. Various groups are also working on developing ultrafast lasers with kW power. It seems only a matter of time before these will be available to industry.

Special Forums on Process Monitoring and Additive Manufacturing

Participants in the full-day forum on laser additive manufacturing were also agreed that productivity is the key to the wider spread of additive manufacturing techniques. Components made using additive manufacturing techniques have already proved to be game changers in turbine construction, and we are seeing constant stream of new applications in aircraft design and the automotive sector. Multi-beam approaches could be a way to ensure even more widespread use, a corresponding project at Fraunhofer ILT is aiming to increase productivity thirtyfold.

The new forum on process monitoring attracted a good crowd, with the number of attendees far surpassing organizers’ original expectations. Presentations looked at various sensor systems and experiences in implementing process monitoring systems in an industrial context. Here, inline measurements are becoming more and more widespread. Great progress has been made on the various sensors; the problem now has to do with evaluating individual images, as the rate of pseudo errors is often still too high. Understanding of many processes also remains limited, which restricts the chances of an effective simulation.

In order for users to share their experiences regarding the increasingly varied and complex processes more efficiently, the “Industry working group for process control in laser material processing” has now been set up in Aachen.

Growing Complexity and Dynamic Market Movement

In the Gerd Herziger session, representatives from TRUMPF, ROFIN-SINAR, Coherent and JENOPTIK discussed the outlook and challenges for various markets. Peter Leibinger (TRUMPF) took a look at the lightweight engineering market and observed that though this is a big market for laser technology, it consists of many niches experiencing moderate growth. However, he assessed the requirements in these niches as complex, leading to high development costs. In his opinion, the only chance for growth in this market is to open up new niches or drive out other providers from the marketplace.

Mark Sobey (Coherent) gave a talk on the semiconductors and electronics market. He expects to see more use of fast and ultrafast lasers at reduced cost per watt. In his estimation, no one platform would be likely to emerge victorious; the crucial factor will be adapting processes to the applications. With a view to the increasing labor costs in China, Sobey expects to see a surge in automation technology. He believes the greatest challenge lies in offering fast global service for the various applications in question.

In the subsequent discussion, all participants agreed on the need for more efficient development processes. However, opinion differed as to the merit of expanding cross-sector partnerships, Leibinger seeing it as an effective way forwards and Sobey rejecting the approach, pointing to bad experiences in the telecoms sector.

Photonics Cluster: Networking 4.0!

Fraunhofer ILT can look back on a long history of success when it comes to the partnership between industry and research. This year a new chapter began on April 28, 2016 with the ceremonial opening of the first building of the Photonics Cluster on RWTH Aachen’s new campus.

Here, companies from industry will work with experts from RWTH Aachen University and several of the Fraunhofer Institutes on new projects focusing on the use of light as a tool in industrial production. Picking up on the creative atmosphere of start-up companies, there will be scrum areas as well as conventional offices and laboratories. Teams will be able to develop ideas together in large open-plan spaces.

At the ceremonial opening, Professor Reinhart Poprawe, director of Fraunhofer ILT and the Photonics Cluster, announced that 90 percent of the space has already been rented out. The first 150 employees will move in over the next couple of weeks, including those from the Aachen Center for Additive Manufacturing ACAM. Members of this center include various Fraunhofer Institutes, departments of RWTH Aachen University and Aachen University of Applied Sciences, as well as technology-focused spin-offs near the RWTH Aachen Campus who work with companies from the region as well as big international corporations. The focus is on training and contract research into additive manufacturing. Fraunhofer ILT and its network in Aachen also coordinate the Digital Photonic Production strategic research initiative funded by the German Federal Ministry for Education and Research. Over the next 15 years, this initiative will providing funding of up to two million euros a year for industry-relevant projects dealing with additive, ablative and structuring laser techniques.

Summary

The opening of the Photonics Cluster at AKL’16 saw the beginning of a new chapter in the cooperations on the development of industrial laser technology. Here partners from research, Fraunhofer Institutes, and companies big and small will come together in an open, collaborative environment with state funding to bring new ideas from the laboratory to the marketplace. Over the coming years, the other clusters will be added to the new RWTH Aachen Campus, thus lending the networking of research and industry an interdisciplinary dimension.

There was much discussion at AKL’16 about the growing complexity of materials and processing techniques as well as new trends such as industry 4.0. Participants also felt that the development of new technologies must become faster at the same time. The closer collaboration between research and industry afforded by the new RWTH Aachen Campus could be a good way to come to terms with this complexity and dynamic movement. At the very least, it seems a very promising concept in terms of leveraging and bolstering local advantages to maximum effect with a view to global competition, as well as offering the opportunity to make a worthwhile contribution to megatrends of social import.

Supporting Organizations of the AKL

- Arbeitskreis Lasertechnik AKL e.V.

- European Commission

- EPIC – European Photonics Industry Consortium

- European Laser Institute ELI e.V.

- OptecNet – Innovation Networks for Optical Technologies

- SPECTARIS – German Industry Association for Optical, Medical and Mechatronics Technologies e.V.

- VDA – Association of the Automotive Industry e.V.

- VDI – Technology Center GmbH

- VDMA – Association of German Machinery and Plant e.V.

Dates & Links

- ICTM – Conference, February 15-16, 2017, Aachen, Germany:www.ictm-aachen.com/en/Conference

- UKP Workshop 2017, April 26-27, 2017, Aachen, Germany: www.ultrakurzpulslaser.de

- International Laser Technology Congress AKL’18, May 2-4, 2018, Aachen, Germany: www.lasercongress.org

- Industry Working Group for Process Control in Laser Material Processing: www.laserprocesscontrol.org

- Aachen Center for Additive Manufacturing ACAM: www.acam.rwth-campus.com

- Center for Digital Photonic Production DPP: www.dpp.rwth-campus.com